19 January 2023

For those who didn’t follow our post last week, we are starting a series called Vida sem Minação. The objective is to make people, in general, aware that mining activity is present in several areas of our lives. Some of them we didn’t even imagine. In this first text, let’s understand that, without the mining […]

Read more

15 May 2023

The Brazil Iron Plan for the Recovery of Degraded Areas (PRAD) has surpassed the milestone of two thousand planted seedlings since its implementation. Nearly R$100,000 has been invested in restoring regions that currently lack vegetation and maintaining the preservation of natural resources. With the acquisition of inputs and substrates to assist in the production of […]

Read more

17 May 2023

Brazil Iron recently initiated a fauna survey process in the region. This work, the largest and most comprehensive ever conducted in the area, will encompass the municipalities of Piatã, Abaíra, Jussiape, and Mucugê. Several cameras that can capture images in extremely low light conditions have been installed in various locations. The equipment features technology that […]

Read more

26 May 2023

The City Council of Jussiape received a team from Brazil Iron on Friday, the 19th, for a presentation on the activities carried out in the city. The work is in the research phase and includes the regions of Bicho, Contendas, Palmeiras, Lagoinhas, and Bananeira. Representatives of the local population were able to gather more information, […]

Read more

02 June 2023

News! Another way to connect with us! 👥✉️ Brazil Iron has created the Virtual Question and Suggestion Box as a way to listen and address the concerns of those living in the region! Now, you can send your questions, doubts, and suggestions quickly and conveniently through our social media channels. How to send your messages: […]

Read more

05 June 2023

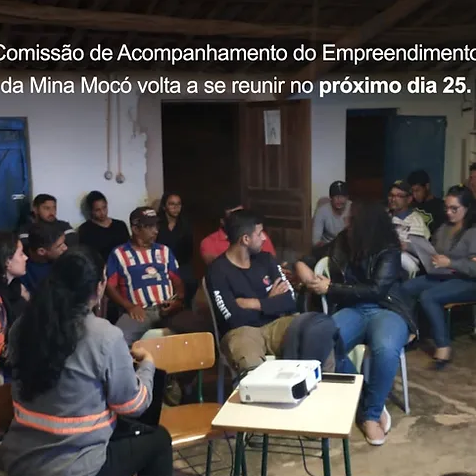

The Falhado community hosted the 13th meeting of the Mocó Mine Development Monitoring Commission last week. The meeting took place at the Association of Horsemen in that locality, located in the rural area of Piatã. The Environmental Impact Study and Environmental Impact Report (EIS/EIR) remained the main topic of discussion, and participants were able to […]

Read more

17 January 2023

The Monitoring Commission for the Mocó Mine Project will have its first meeting of the year in January. The conference will take place on the 25th Wednesday, at the building of the Community Association of Small and Mini Rural Producers of Bocaina and Tabua (ACPMPRBT). Some subjects are scheduled on the agenda, such as the […]

Read more

13 January 2023

You must have already read, heard or witnessed several demonstrations trying to end mining activity. Unfortunately, these groups often convince the press, politicians and ordinary citizens. Nobody explains what would happen to our lives if there were no more iron ore extraction and other raw materials. In the coming weeks, we will bring examples of […]

Read more

11 January 2023

A preview of the 2022 IBGE census released recently points out that the population of Piatã has surpassed the mark of 20 thousand inhabitants. Compared to the 2021 figures, the growth represents around 20%. According to the Institute, the municipality has 20,098 people, against 16,864 registered in the previous year. The advance is one of […]

Read more

21 November 2022

With the arrival of November, we have the beginning of the Blue November campaign. Brazil Iron supports the cause and will carry out awareness activities throughout the month. The beginning of the activities took place with the employees of the maintenance sector, with clarifications on the subject. In 2011, the Institute launched Blue November in […]

Read more

19 November 2022

On October 26, a Participatory Workshop was held with the residents of locations around the Mocó Minerário Complex. The objective was to raise the population’s real needs and expectations concerning the enterprise and identify the potentialities of these communities. The data collected aims to support the “Program to Support the Development of Rural Productive Activities […]

Read more

16 November 2022

Speciality coffee produced by Antonio Rigno de Oliveira Filho at Fazenda Tijuco, champion of the Cup of Excellence 2022, the world’s leading quality contest for the product. The 2002 vintage gave the family their fourth title in the competition, following 2009, 2014 and 2015 achievements. With a score of 91.41 points, out of a possible […]

Read more